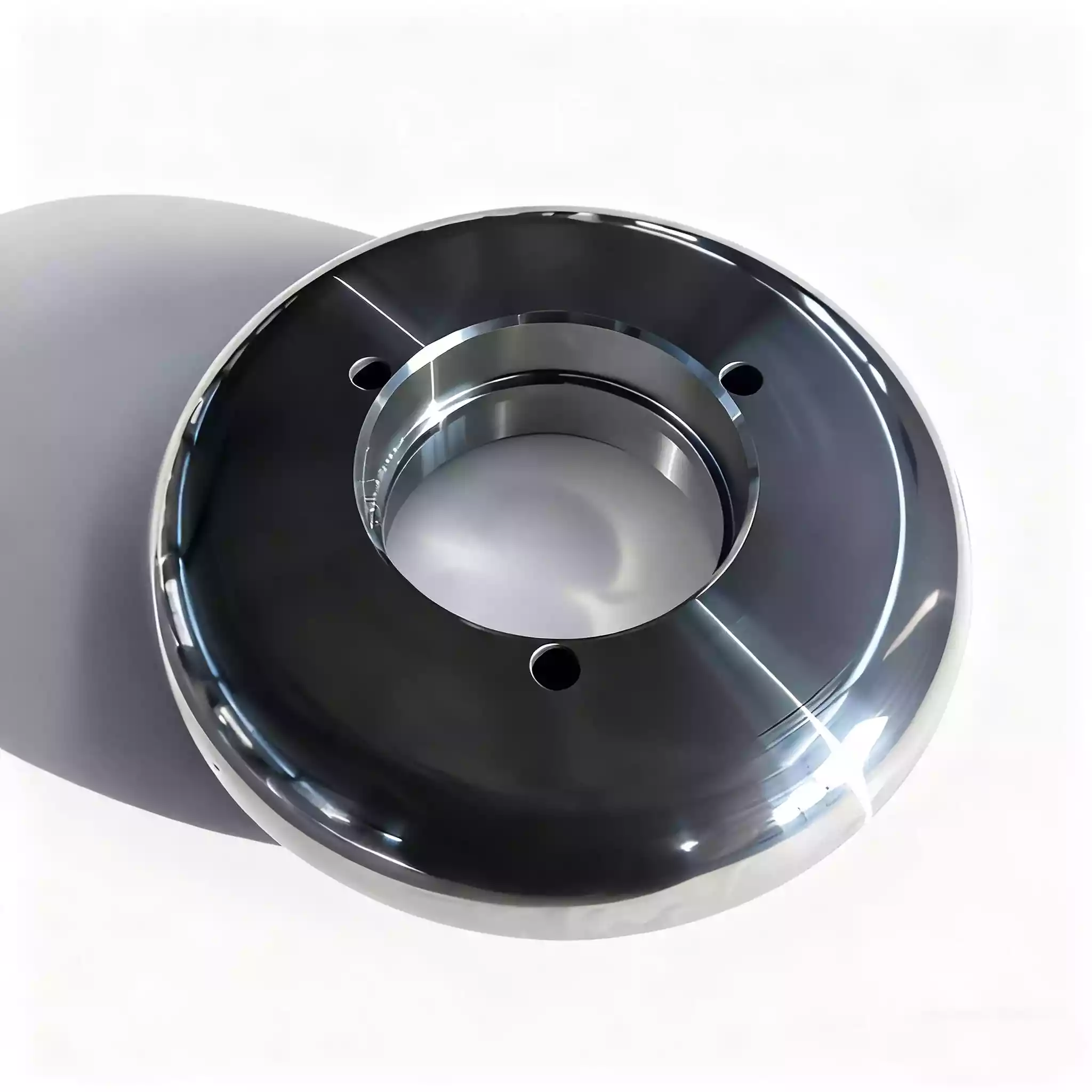

High-Precision Spinning Rollers & Tooling for Metal Forming

Durable, accurate, and factory-made to your drawing or sample. Ideal for metal spinning and flow forming lines—engineered profiles, CNC ground surfaces, and consistent performance.

Durable, accurate, and factory-made to your drawing or sample. Ideal for metal spinning and flow forming lines—engineered profiles, CNC ground surfaces, and consistent performance.

Spinning rollers (also called spinning heads or flow forming rollers) are consumable tools used to form sheet metal into precise cylindrical or conical parts. They deliver high surface finish and tight dimensional control in metal spinning and flow forming operations.

Keywords: spinning roller, spinning tooling, metal spinning head, flow forming roller.

Yes. Send drawings/specs; we manufacture to your requirements.

Typically 20–30 days depending on quantity and profile.

Looking for reliable spinning rollers or metal spinning heads? Email us your drawing/specs and we’ll reply quickly with pricing and technical advice.

Prefer a form? Fill this out and we’ll reply fast. For drawings or large files, please email us directly: jerrywcnc@gmail.com.